The first Dutch carbon capture and storage plant is taking shape

For the new episode of Road to 2050, Mauro Mereu visited the construction site of Porthos, the first Dutch carbon capture and storage project.

Published on October 28, 2024

Mauro swapped Sardinia for Eindhoven and has been an IO+ editor for 3 years. As a GREEN+ expert, he covers the energy transition with data-driven stories.

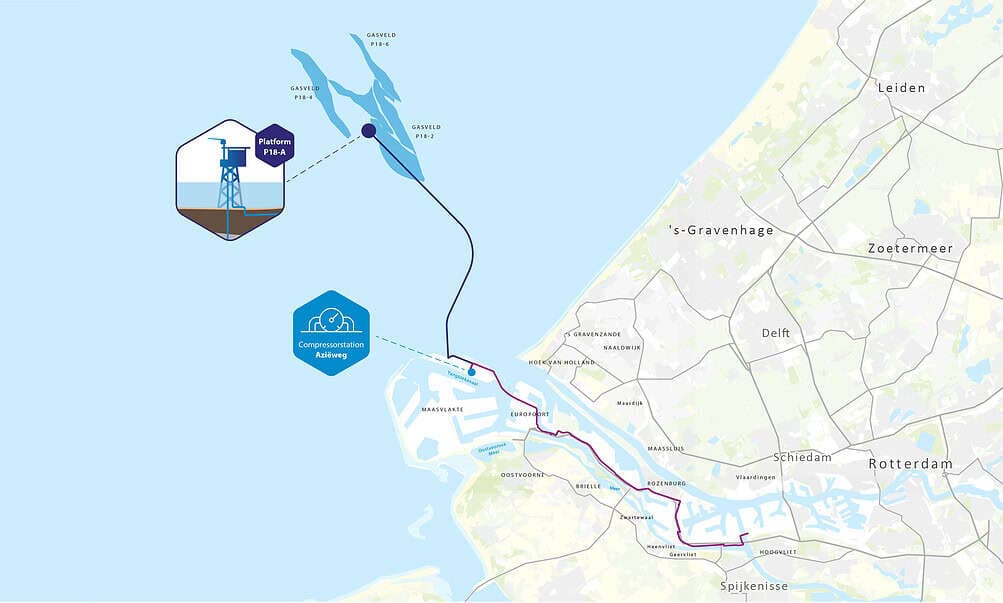

The first Dutch carbon capture and storage (CCS) project is not a common one. Its name is Porthos, and it will store, in a depleted gas reservoir 20 kilometers off the coast, CO2 captured from industrial plants in the port of Rotterdam. Works started earlier this year, as the infrastructure will be operational by 2026. The system will capture and store 2.5 metric tons of carbon dioxide annually.

The final investment decision was made in late 2023, following a seven-year-long process, kicking off works on several locations along the pipeline route. The initiative is a European Union Project of Common Interest and received €102 million from the Connecting Europe facility. A consortium comprising the port of Rotterdam, Gasunie, and Energie Beheer Nederland (EBN) are the initiators of Porthos.

I took a driving tour of the different construction sites along the route with Mark Driessen, who is responsible for Porthos's stakeholder management. After several years at the Ministry of Economic Affairs, he started working for the port right when Porthos was in its early stages. “While in the beginning, it seemed a complicated endeavor on many fronts, Porthos construction finally started and is now ‘merely’ an engineering project with technical challenges to overcome,” he says as we drive out of Rotterdam city center towards the port.

Road to 2050

It might seem far off, but 2050 is 26 years away. 2050 is the year set by EU countries to become climate-neutral, aligning with the targets previously set by the Paris Agreement. What does climate neutral mean? For a service, process, or product to be climate neutral means that all greenhouse gases it produces are offset by climate measures. Although reducing emissions is the primary way to achieve climate neutrality, this does not mean there are no emissions; they are offset through support for climate protection projects. What steps do we need to take to achieve climate neutrality? How do we make our economy climate-neutral? In Road to 2050, we will look at the challenges we need to overcome.

A network of underground pipes

Porthos is set to be operative for 15 years, meaning that 37 million tons will be stored in total. A ton of carbon dioxide equals a 500 m3 hot air balloon, so a metric ton is as big as a thousand such balloons. The EU targets 50 million tons of carbon dioxide stored annually by 2030.

While driving through the onshore stretch of the CO2 corridor, black tube sections, having a diameter slightly larger than a meter, await to be laid down as bulldozers and excavators–now parked as it’s a Friday afternoon—prepare the terrain. The route starts at Shell Pernis’ refinery. From there, 30 kilometers of pipelines reach the compressing station, and from there, the tube extends for 20 kilometers on the sea to reach the offshore platform. The oil and gas company is one of the four customers, alongside Exxon Mobil, Air Liquide, and Air Products, whose plants are along the pipeline route.

“The most complicated part to build is the first stretch. That is in the oldest part of the port, where pipeline t designs are more complicated and not as organized as in the newer harbor area,” says Driessen, seeking a safe spot to park the car temporarily. As I get out of the car, the complexity of the pipelines housed in the port subsurface becomes clearer to me. The CO2 pipeline sits beside water, sewage, and gas tubes.

Safety

The journey continues. The road we drive on crosses a busy highway overpass, and a part of the pipeline will also move up the ground and follow the bridge line. Every now and then, the black pipe sections appear again. Next to the highway, tens of them await to be moved and laid. In total, over 4000 sections are needed to complete the CO2 corridor.

The pipeline stretches along the left side of the road. On the right-hand side, behind a straight line of trees, there is the town of Rozenburg. Part of the Rotterdam municipality, the village is home to over 13,000 inhabitants who have been involved and informed about the extent of the project. Most of the citizens' concerns were about the safety of the infrastructure.

“Being open and honest about the project is the best way to approach discussion with citizens. Telling them what you know and being transparent about what you don’t know helped to gain their trust,” Driessen explains.

Before getting approval, Porthos conducted studies to assess the potential risks connected to CO2 transport. Although carbon dioxide is not flammable nor explosive, having it in high concentrations in the air can be harmful. To counteract potential leaks, in the stretch bordering Rozenburg, the conduit will be equipped with extra shutters to activate should a leakage occur.

Compressing CO2

As the journey continues, there is time for a brief stop at the port office Porthos has. A wall-sized map in the hallway shows an aerial view of the project, which does justice to the grandeur. After a quick coffee and a chat, we leave again, reaching the very last onshore stretch of the pipeline.

So we reach the next destination, the compressor station. “CO2 must be further pressurized to be injected 3 kilometers under the sea surface. In fact, until reaching the compression station, carbon dioxide flows through the pipeline in a gaseous state with a pressure of 35 bar, not enough to be injected,” clarifies Driessen. The compressor site is located in the Maasvlakte—a man-made extension of the Rotterdam port—just before the pipeline continues into the waters and brings CO2 pressure to a maximum of 130 bar.

Construction works, led by the Italian firm Bonatti, have started at the site. Preparations to lay the foundations of the compressor building are in full swing. Given the stringent safety requirements for the pipeline, only authorized, trained personnel can access the construction works, so we can’t access the area.

There, three compressors will work to pressurize carbon dioxide further. Powered by local green power, the compressor building is complemented by a pumping station, where cooling water pumps bring down the compressors’ temperature.

© Porthos

Beyond Porthos

Crucially, this point is a very strategic one within the port of Rotterdam’s present and future CCS projects. For example, the Aramis project, currently in the discussion and approval process, will also store CO2 in North Sea reservoirs. Using the same compressor station of Porthos, Aramis plans to inject carbon dioxide into the depleted gas reservoirs off the coast of the North of the Netherlands.

Besides, CO2next, a partnership between Gasunie, Vopak, Shell, and TotalEnergies, wants to create a liquid CO2 terminal on the Maasvlakte. The project plans to create a central hub for unloading, loading, and storing carbon dioxide in North Sea reservoirs.

No panacea

From there, the pipeline continues its route below the sea wall and straight to the offshore platform. It is a sunny day, and the sky is perfectly clear; we can see the platform from the seawall. A wind turbine hovers above us.

The Saudi Arabian company TAQA is the owner of the former gas extraction infrastructure, once used to extract gas from the now-almost-empty fields P18-2, P18-4, and P18-6. While the structure will remain the same, the pipes and instruments needed to pump gas will be replaced by some apt for CO2 storage. The wells also need some readapting to transform into carbon dioxide injectors. In addition, solar panels and a windmill will provide the platform with green power. The sea platform will also be connected digitally to the compressor station to synchronize the two systems.

2026 is around the corner. Since then and for 15 years, the pipeline will be up and running. What about after? “CCS is necessary now and will still be needed to offset emissions, but I hope fossil-fuel related CCS will be needed for the shortest possible time,” concludes Driessen.