Carbon capture and storage: where are we now?

Carbon capture and storage is set to be instrumental in reducing CO2 concentrations in the atmosphere. In the third episode of Road to 2050, we dived into it and the developments that need to happen.

Published on September 18, 2024

Mauro swapped Sardinia for Eindhoven and has been an IO+ editor for 3 years. As a GREEN+ expert, he covers the energy transition with data-driven stories.

Unfortunately, fossil fuels won’t be phased out suddenly. Our dependence on them is forecasted to be lower, but we will still be (partly) relying on them for the decades to come. Emissions won’t go down to zero then, and climate neutrality scenarios don’t forecast a total zero emission scenario. It’s often misunderstood, but climate neutrality means offsetting emissions through climate measures. How do we compensate for the – hopefully low – emissions we will still produce? Planting trees for sure, but scientists see carbon capture and storage (CCS) as essential to diminish atmospheric carbon dioxide concentrations.

CCS is a term that encompasses a vast range of technologies that sequestrate carbon dioxide from the atmosphere and store it underground. The technology usually involves capturing CO from large emitters like industrial plants. Carbon dioxide is then compressed and transported to be injected into the subsurface, mainly in depleted oil and gas reservoirs – as done by the oil and gas industry to recover more fuel from deposits.

Targets and challenges

The European Union set targets for the amount of captured carbon. By 2030, 80 million tonnes should be sequestrated, and by 2050 – the deadline for climate neutrality – 550 million tonnes. Currently, the biggest operating facility in Europe is in Iceland; Climeworks’s Mammoth plant opened last May. The International Energy Agency (IEA) reports 45 active facilities worldwide, mainly in the US. The high costs remain the barrier to be overcome on the way to a broader technological adoption. Estimates suggest a price of €70-250 per tonne of sequestrated CO in Europe. IO spoke with Samatha Eleanor Tanzer, an assistant professor at the Delft University of Technology (TU Delft), researching carbon removal systems, and Marco De Paoli. He’s a Marie-Skłodowska Curie Fellow at the University of Twente (UT), mainly focusing on carbon storage.

Taking stock

There are three main ways to capture carbon dioxide: pre-combustion, post-combustion, and oxy-fuel combustion methods. In pre-combustion, removal happens before combustion occurs, gasifying fossil fuels – such as oil, coal, or natural gas – into a mix of hydrogen and CO. The former is used as fuel, and the latter is captured and separated. The post-combustion removes CO from exhaust gases, which pass through solvents. Oxyfuel combustion processes burn fossil fuels in pure oxygen, producing a flue gas, a mix of vapor and carbon dioxide. The vapor is easily condensed, easing separation.

Post-combustion is ideal for cement production. In fact, even if cement plants were powered using low-carbon power, they still generate lots of emissions due to calcination – namely, the heating of limestone. Pre-combustion CCS is essentially hydrogen production and fits many processes in the chemical industry, such as fertilizer production. To this extent, Tanzer sees CCS as a low-hanging fruit where there are high-purity streams of CO or where carbon dioxide is a non-combustion byproduct. “Ultimately, it will be a mix of processes depending on the industry. In general, the more concentrated carbon dioxide is in the gas stream, the easier it is to capture it,” she clarifies.

Storage safety

One of the concerns is about the safety of underground storage sites. Researchers are investigating how carbon dioxide behaves underground and if its movements can lead to earthquakes. “Let’s think of an underground carbon storage as a giant box containing water. The CO is lighter than water, so it tends to stay above it. The box’s lid – a rock stratum, ed. – blocks this movement. This lid can break if someone drills a well or if there are already existing fractures. This leaking mechanism doesn’t happen overnight, but it might take 50 or 100 years,” explains De Paoli.

To this extent, monitoring movements is essential to assess safety. There are two main ways to monitor underground carbon storage sites. One uses seismic surveys: sound waves are emitted from a source to a receiver. Depending on the time it takes to reach the receiver, scientists can understand the rock’s composition and where the CO is.

The other one is using satellite images. An example of this method application is for monitoring the In Salah site in Algeria. Since this site is located in the desert, scientists could have clear imagery and notice how the soil moved up by a few centimeters close to where the injections happened. There, carbon dioxide was stored 3000 meters below the surface and pushed the soil layers on top of it. “At the moment, there is not a full answer to the possibility of CCS causing earthquakes. According to some, fracking – the injection of fluid below the surface ed. – can indeed result in earthquakes. The truth is that more research needs to be done, and we need to understand what happens in the longer term,” the UT academic underlines.

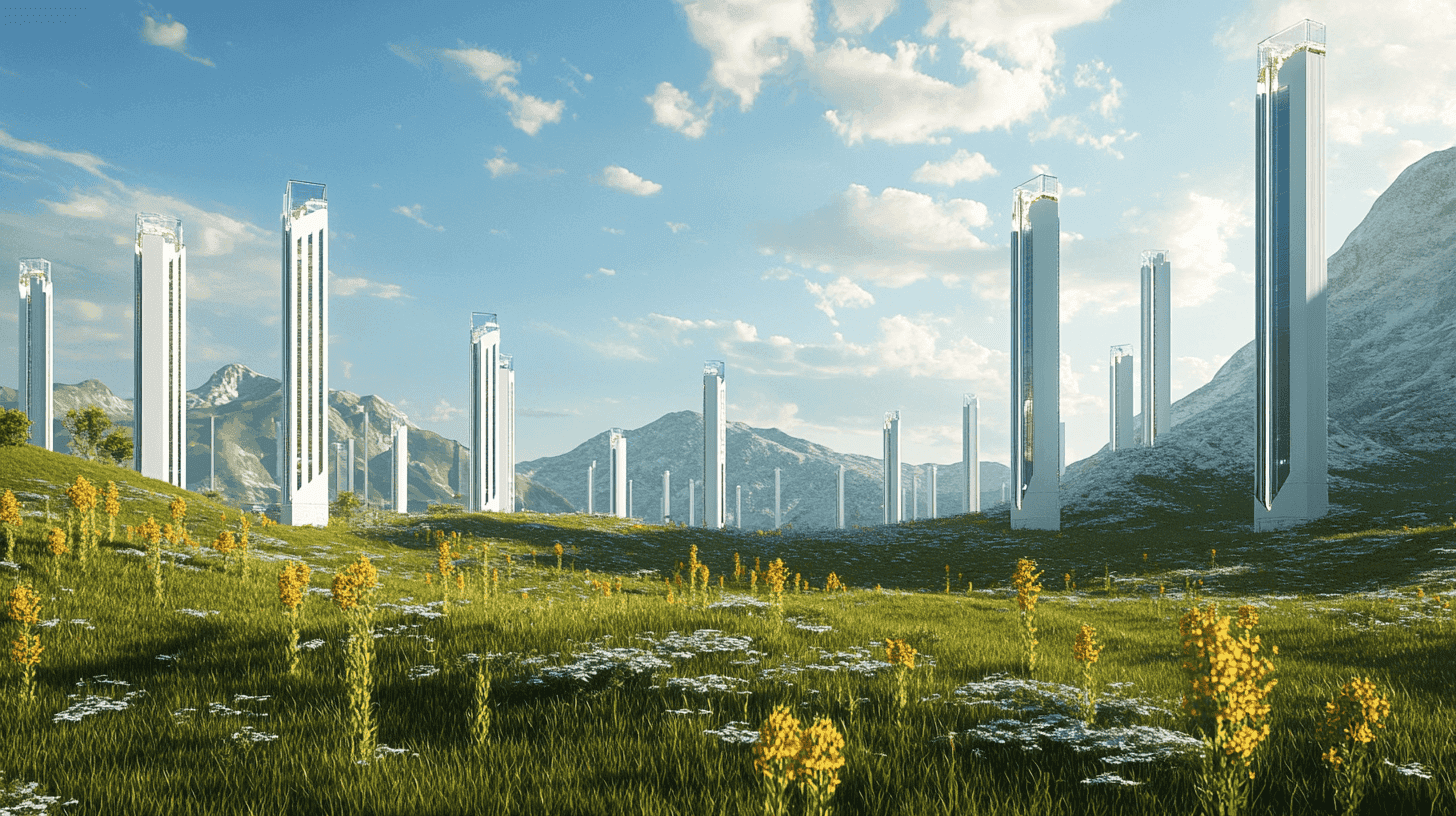

The rising alternative: direct air capture

In recent years, direct air capture (DAC) gained momentum. DAC systems use large fans to pull air into a collector where carbon dioxide is chemically separated from the air. Unlike other carbon capture technologies, DAC can be deployed anywhere. However, since the CO concentration in the air is lower, sequestration is complex and requires high energy inputs. In the United States, the federal government deployed $7 billion in grant funding to develop DAC hubs and over $13 billion in tax credits to promote carbon sequestration and technology development. In the Netherlands, companies like Carbyon and Skytree have also taken significant steps to develop this technology.

“A relevant advantage of using DAC is the possibility of clearly assessing how much carbon dioxide is being extracted. The biggest hurdle to its deployment is the high cost of regenerating absorbing materials,” explains De Paoli. In addition, he points out that if it were not done with clean power, it would emit more carbon dioxide than it would capture.

According to Tanzer, DAC needs to be in the portfolio of climate-mitigating solutions but should not cannibalize the efforts to avoid carbon dioxide from entering the atmosphere, given the efforts required to sequestrate it. “Ideally, DAC should be deployed where CO storage is available and where there is a low carbon energy source that is not easily used. A good example is Climeworks’ Mammoth, where geothermal power and underground storage are not easily accessible, so DAC can be co-sited and take advantage of resources that would otherwise be tough to use,” clarifies the researcher.

The prospects

Both researchers see the decrease in cost as essential for the broader deployment of any CCS technology. “There is another way to look at CCS: as a mandated option to make fossil fuels more expensive. Do you want to use coal? Then, you must have a carbon capture system to compensate for those emissions. It makes it less appealing to use fossil fuels and provides a more level playing field for renewables and other decarbonization options,” suggests Tanzer. In her view, paying for transport costs is the main bottleneck. To slash costs, she suggests operating carbon pipelines as a public utility.

In De Paoli’s view, much of the fate of CCS will depend on the availability of affordable and reliable technologies. “Being able to store COfor at least 10,000 years for less than $100 per ton, monitoring risks and effects on the environment and people should be the goal. To attain it, we need valid infrastructure in every process phase. The question is not whether we should do it but how much work needs to be done in the coming years,” he concludes.