'We often don't realize the power at our disposal'

For this new episode of the Green Transition Drivers series, IO spoke with Lori Goff, founder of sustainable packaging company Outlander Materials.

Published on September 20, 2024

Mauro swapped Sardinia for Eindhoven and has been an IO+ editor for 3 years. As a GREEN+ expert, he covers the energy transition with data-driven stories.

Not Iron Man, Batman, or Spiderman. Lori Goff’s favorite superhero was Captain Planet. In every episode of its TV show, the world is in peril, and he would come and help his five planeteers save the world from pollution. His feats and the learnings of each episode had an impact on Goff, who, since her childhood, felt the responsibility to do something for the environment. Fast forward to 2024, she accepted the challenge. “We all have more power than we realize,” she says.

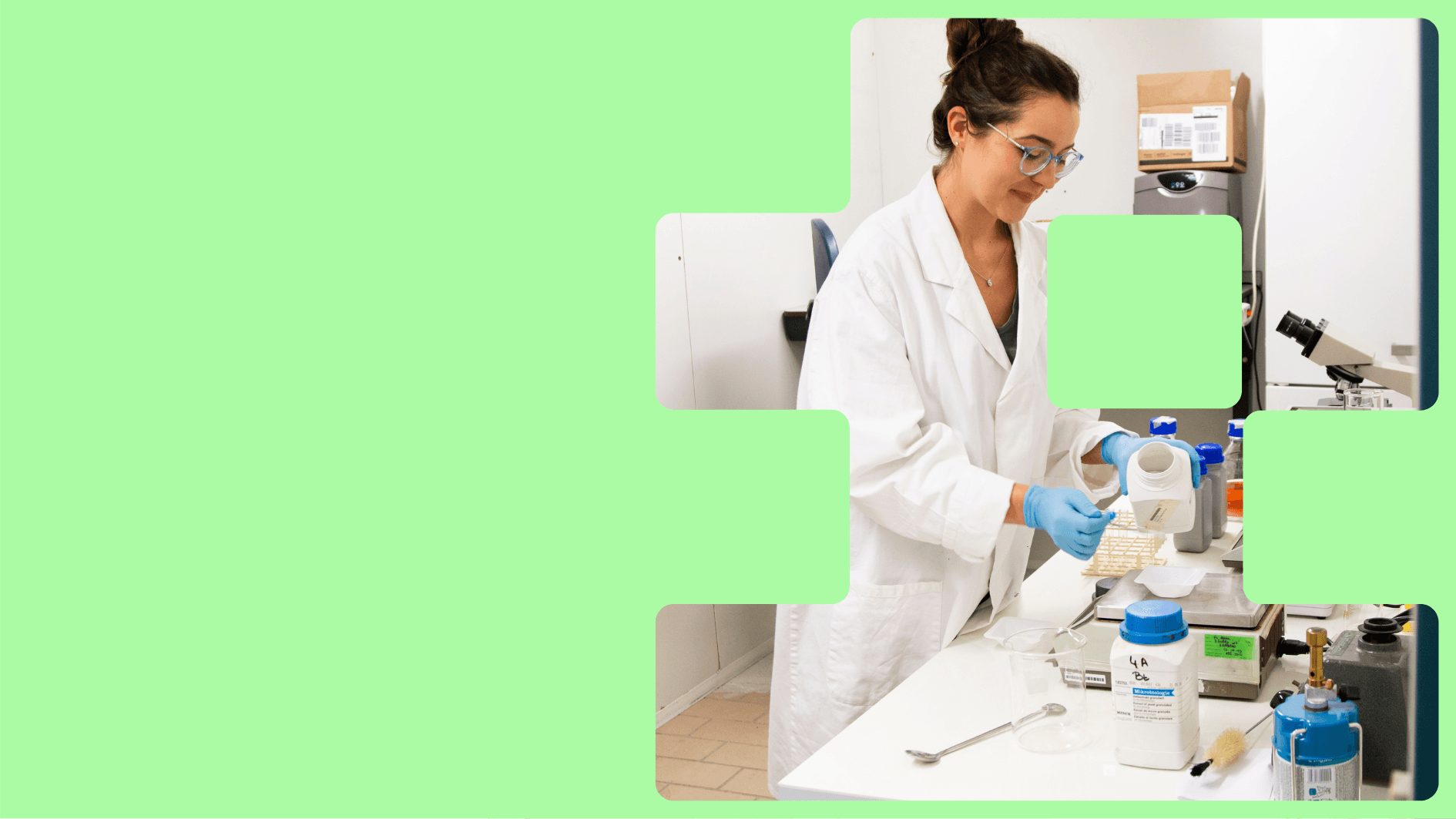

Born and raised in Nebraska (United States), Lori Goff studied biotechnology at the University of Omaha. “It sounded wonderful being able to grow algae on wastewater and turn it into biofuels, and this education would give me the foundation to work on these types of initiatives,” she recalls. While finishing her thesis, Goff moved to the Netherlands and started working on different projects. It was in 2018 that she founded Outlander Materials, with the idea of creating new packaging materials using organic sources. The result was UnPlastic, an alternative to single-use plastic sourced from beer brewing side streams.

In addition to being biodegradable and non-toxic, UnPlastic is flexible, lightweight, and capable of extending food’s shelf life. Reducing virgin resource usage, offering high-quality packaging, and slashing plastic waste are the three problems for which Outlander Materials wants to provide a solution. If the drive to do something impactful for the environment was always there, Goff’s intuition behind UnPlastic was brewed from her kitchen.

.png&w=2048&q=75)

The Green Transition Drivers

Reducing emissions, optimizing resource use, and adopting green energy are some of the practices we need to adopt to transition towards a greener economy. But who’s behind the green transition? In our series, The Green Transition Drivers, we spotlight entrepreneurs and innovators working to make our economy greener.

The eureka moment

For one of her birthdays, Goff received a brewing kit. While crafting her own beer, she realized how much waste this process produces. Her biotech background kicking in, the soon-to-be startupper decided to talk with some breweries in Rotterdam to see what could be done. At BlueCity, a then recently opened circular economy hub with lab spaces, Goff knocked at the door of Vet & Lazy, offering to work for free to study the brewing process closer. She could start experimenting with some brewing waste samples.

“It was a Saturday morning in August when I went to the lab to check some of the experiments, and I noticed the experiments were developing just as I had expected. I realized it was possible, even though I didn’t know at that time how challenging it would be,” she recalls.

Growth

And the Outlander Materials adventure began. In the very beginning, it was a one-woman band, with Goff conducting research, seeking investors, and capitalizing on some early media attention. The turning point came in 2019, when, thanks to a Rotterdam city grant, she could hire the first employee and rent a space at BlueCity. “It was life-saving and life-giving! The company wouldn’t be here without that grant.”

Since then, the concept hasn’t changed much– yet it has evolved and is backed by rigorous intellectual property. The process works with low-value side streams from food production and agriculture and transforms into functional packaging through fermentation and material science. With this same concept, UnPlastic became a valuable alternative to films, coatings, and single-use plastics in general.

At this moment, the startup is working with some packaging companies and focuses on scaling its processes from lab scale to pilot production. Goff: “We are working with a new material, and while that brings many new challenges to overcome, it also brings a great deal of potential.” Being the UnPlastic a new material, new production lines that can accommodate industrial production need to be set, for instance.

Leading and inspiring

Five people currently work at Outlander Materials. Goff also learned to lead a company and transfer her drive to the other team members. She initially felt nervous about such a role but now feels comfortable in her CEO position. “Building the company I wish I could have worked for while working on technology that can be instrumental in tackling climate change is what I enjoy the most,” she says.

Goff’s passion extends beyond her company, as she shares her experiences and mentors fellow entrepreneurs or those on the verge of starting their own ventures. The key lesson she emphasizes is embracing failure and difficulty. “Leading a startup is endlessly challenging—it’s hard!' she admits, “but learning to embrace this can transform the pain and struggle into an incredible adventure.” She often finds that aspiring entrepreneurs need someone to talk things through with, reflecting her belief that many people underestimate each individual's power."

Need to move

As an entrepreneur and firm environmentalist, Outlander Materials CEO advocates for bolder actions to enact the systemic change needed to undertake the green transition. “There is a lot of comfortable talk. Targets and plans for 2030 or 2050 always feel like a distant timeline. Big companies are in a comfortable position and are not forced to take action. Faraway bands are not enough; we need a crisper setting and tangible plans,” Goff stresses.

Despite the amount of work still needed to make UnPlastic a commercial product, the ambition is high. The vision is to have factories all over the world that could reuse local waste streams to produce the material. Captain Planet would surely be proud.