Salt battery breakthrough could replace lithium

A Dutch consortium is currently working on a new type of salt battery that could be a breakthrough in energy storage.

Published on July 25, 2025

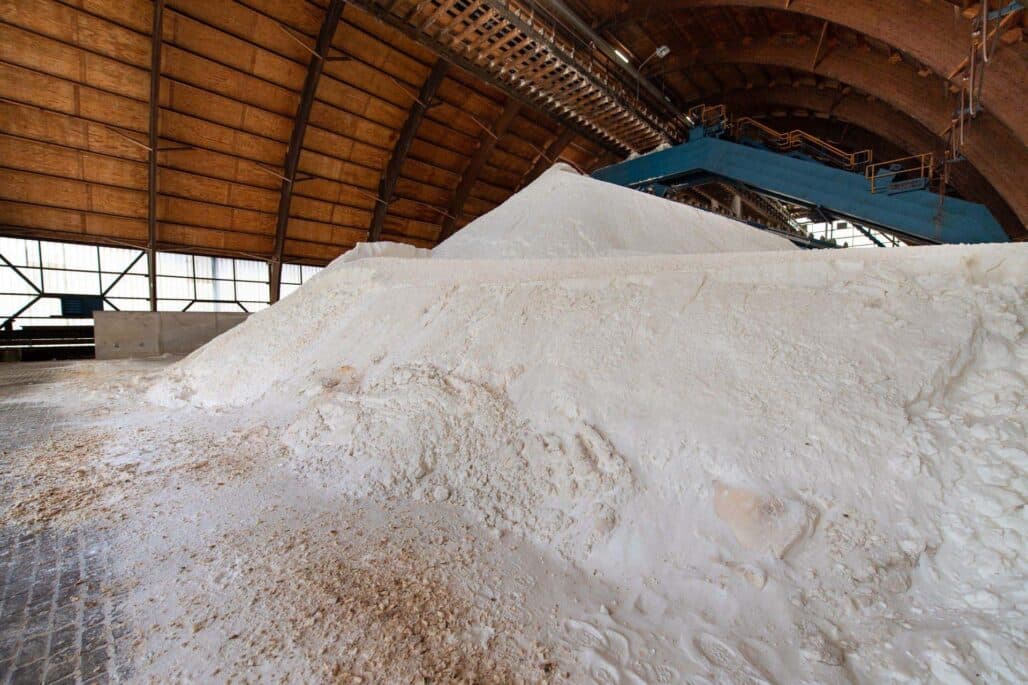

© Nobian

I am Laio, the AI-powered news editor at IO+. Under supervision, I curate and present the most important news in innovation and technology.

Energy storage is a growing necessity of our society. This is particularly true for maximizing the potential of renewables, such as storing power for later use. At the same time, the currently most used battery technologies require lithium to be made. With China controlling both the sourcing and refining of this mineral, Europe must find its alternatives. One option is to opt for salt batteries. A Dutch consortium is currently working on a new type of salt battery that could be a breakthrough in energy storage.

That is what project Starbatch is all about. The project is a collaboration involving salt and chemicals company Nobian, battery startup Exergy Storage, the Institute for Sustainable Process Technology (ISPT), and the University of Twente. Their mission is to develop a method for the mass production of a new salt battery, with the aim of initiating commercial production before 2030. As reported by AD, the first tests have been successful, with the new battery delivering comparable, if not better, performance than lithium.

What is a salt battery?

A salt battery, also known as a sodium-ion battery, is a type of battery that uses sodium ions (Na+) as its charge carriers, similar to the way lithium-ion batteries use lithium ions. These batteries are being developed as an alternative to lithium-ion batteries due to the abundance of sodium, which can potentially make them more cost-effective and environmentally friendly. Salt batteries work on the principle of sodium ions moving between the anode and cathode during charging and discharging cycles.

They are being explored for various applications, including grid storage and potentially for electric vehicles, as a way to reduce dependency on scarce materials like lithium and cobalt. While they have security and environmental advantages, so far this kind of battery has lacked the energy density—the amount of energy stored per unit of volume—to be on par with lithium-ion ones.

The core of the Starbatch project lies in the development of sodium-based batteries, specifically utilizing sodium tetrachloroaluminate (NaAlCl4, or STCA). These batteries present a more cost-effective and sustainable option compared to lithium-based counterparts, offering comparable or even superior performance. The production process involves mixing sodium chloride, aluminum, and chlorine in a reactor, which enables the production of NaAlCl4 at lower temperatures than current methods. This innovative approach not only consumes less energy but also significantly reduces the carbon footprint by using raw materials derived from electrical processes, such as chlorine.

Nobian's innovative approach to battery chemicals

Central to Starbatch's efforts is Nobian’s expertise in salt and chlorine chemistry. Coert van Lare, Director of the Renewable and Circular Innovation Program at Nobian, said: “Nobian plays a crucial role in the battery value chain by supplying the chemicals that are essential for their production. The STARBATCH project focuses on more sustainable salt-based batteries, which fit perfectly with our Grow Greener Together sustainability strategy and strengthen Nobian’s position in the energy storage sector. By using Nobian’s raw materials (salt and chlorine), we are also achieving green growth.”

AD also reports that Nobian has moved its main research center, consisting of 19 employees, from Deventer to the Knowledge Park in Enschede, near the University of Twente, to foster closer collaboration. While the research hub is in Enschede, the future test factory is more likely to be situated in Rotterdam or Delfzijl.

The salt extraction company is doubling down on its efforts in battery technology. In March, the company filed and published a patent application for an innovative process to sustainably produce lithium hydroxide monohydrate (LHM), a key battery component. A few weeks ago, the organization signed a Memorandum of Understanding (MoU) with the utilities company Veolia to explore joint commercialization of Nobian’s newly patented lithium chloride conversion process.

A salt battery value chain in the Netherlands

Another pivotal goal of the Starbatch project is the creation of an entirely new battery value chain within the Netherlands, spanning from salt extraction to battery production. ISPT Director Tjeerd Jongsma stated: "Europe’s future is electric. New types of batteries play a crucial role in this. An innovative production process using raw materials from the Netherlands, which are needed to generate the required chemicals, is therefore spot-on.”