Robotization is human work: even the autonomous factory should be human-centered

Marijke Bergman (Fontys) emphasizes the importance of human involvement in robotization during Technology Update at the Brainport Industries Campus.

Published on November 25, 2024

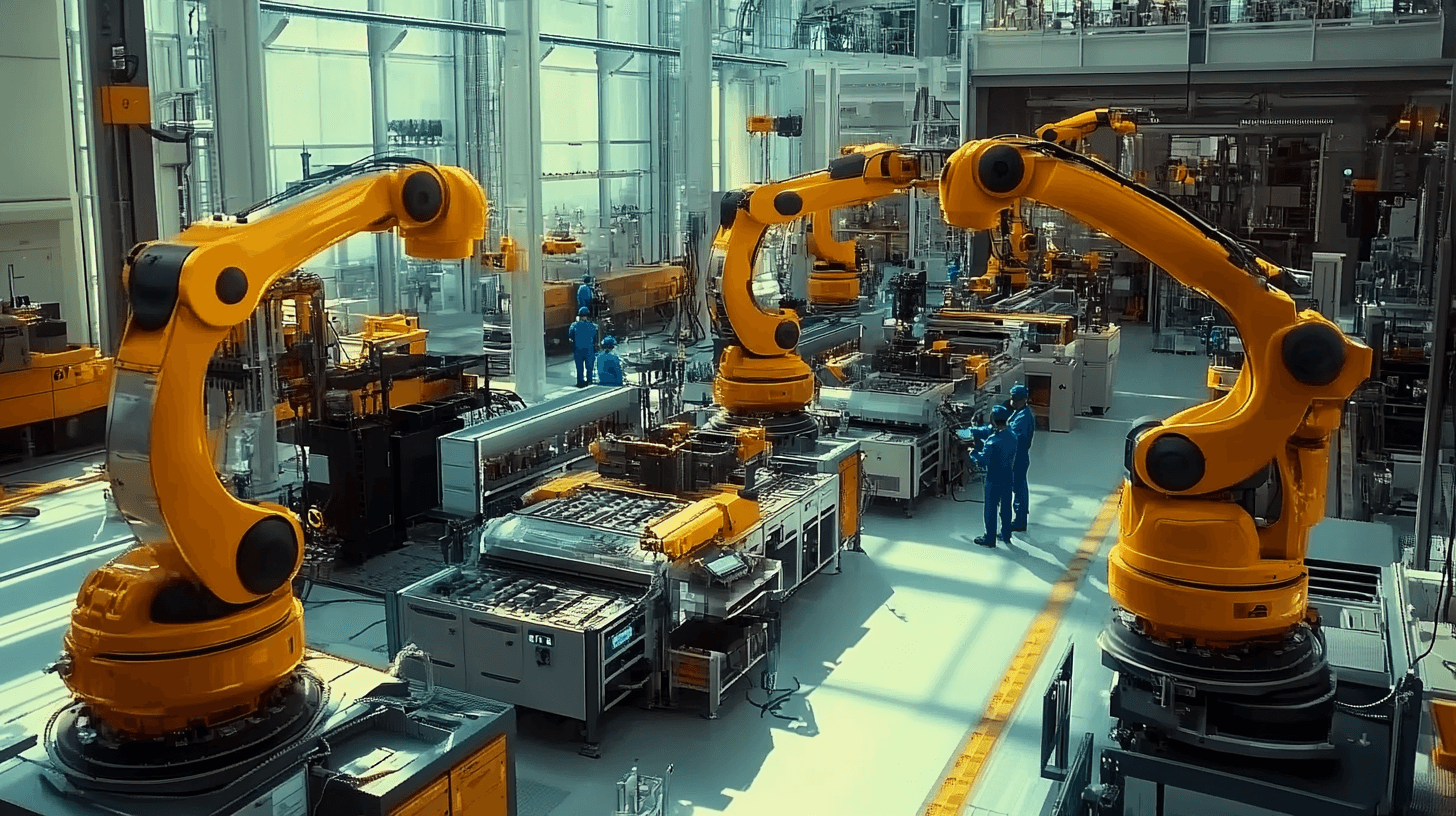

Robots may seem dominant, but the human factor is still at the heart of every factory.

Bart, co-founder of Media52 and Professor of Journalism oversees IO+, events, and Laio. A journalist at heart, he keeps writing as many stories as possible.

Robotization and digitization are transforming the industry. However, according to Marijke Bergman, member of the lectorate of Human and Technology at Fontys University of Applied Sciences, one thing remains unchanged: it is and remains human work. During the Technology Update 'The Autonomous Factory' organized by Brainport Industries, Bergman shared her insights on the crucial role of people in working with (collaborative) robots. The meeting drew over a hundred interested people to the Brainport Industries Campus on Thursday.

“No matter how far we go with robotization, in the end, it is always about humans,” Bergman opened her presentation. It is now impossible to imagine industries such as metalworking, healthcare, and logistics without robots. But despite the advances in technology, humans are still essential. “We need to look at how to design and implement technology in a way that benefits everyone,” she said.

One of the key questions is how robots and humans can work together effectively and enjoyably. “Will that happen naturally? Or is more needed, such as training or custom designs,” Bergman rhetorically asked her audience. According to her, aspects such as work experience, safety, and task distribution are crucial when integrating robots into the workplace.

Figures and trends

Figures from the World Robotics Organization, shown by Bergman during her presentation, show that the use of industrial robots in sectors such as metalworking is increasing by 16%, while in other sectors, such as electronics, it is decreasing. On average, the increase year over year is significant. Yet adoption of collaborative robots, or co-bots, remains limited to just 10% of the total. “There is still a lot of work to be done there,” Bergman stated.

She named trends such as the rise of mobile manipulators, AI, and humanoid robots but emphasized that these developments will only gain value if human interactions are well-designed. “A robot that performs a task independently must be intuitive and understandable. Otherwise, it creates stress and mistrust among users.”

A matter of trust

For Bergman, the key to success lies in trust. “People need to understand what a robot does and why it does it. Understanding leads to trust, resulting in fewer errors and greater safety.”

An example from her research team illustrates this point. During a project with transportation robots, a student discovered that employees felt uncomfortable with the robots' unpredictable movements. The solution? A simple visual indicator, such as a turn signal, so employees knew where the robot was going. “Such seemingly simple design can make a big difference in the collaboration,” says Bergman.

Marijke Bergman, Fontys, © Amber Nijdam

Leaders, technicians, and employees

Multiple parties play a role in the successful implementation of robots. For example, leaders must understand how robotization affects their employees' perception of work. “Are employees involved in decision-making? Do they feel heard? Those are crucial questions,” Bergman said. Education and training, she says, are also essential. “Employees must be given the time and resources to learn how to work with new technology.”

Technicians also have a big influence, Bergman stated. “They determine how a robot looks, moves and reacts. Designs should feel intuitive and natural. If engineers pay more attention to the human experience, they can create more pleasant and effective systems.”

At the same time, employees bear responsibility for themselves. “Adaptability and curiosity are indispensable in a world where technology is constantly changing,” Bergman emphasized. She pointed out that willingness to learn often depends on career stage and social context. “The more people around them are positive about technology, the greater the likelihood of acceptance.”

The future: humans and robots hand in hand

Bergman concluded her talk with a hopeful look to the future: “Well-designed robots and human-centered implementation not only enable more efficient work but also contribute to a better work experience.” She quoted Johan Cruijff to reinforce her message: “Alone you can't do anything; you have to do it together.”