Navigating the uncertainty of climate change as surfing waves

Melchior Krijgsman cofounded with his brothers Entropic, a startup that wants to help factories decarbonize.

Published on November 22, 2024

Mauro swapped Sardinia for Eindhoven and has been an IO+ editor for 3 years. As a GREEN+ expert, he covers the energy transition with data-driven stories.

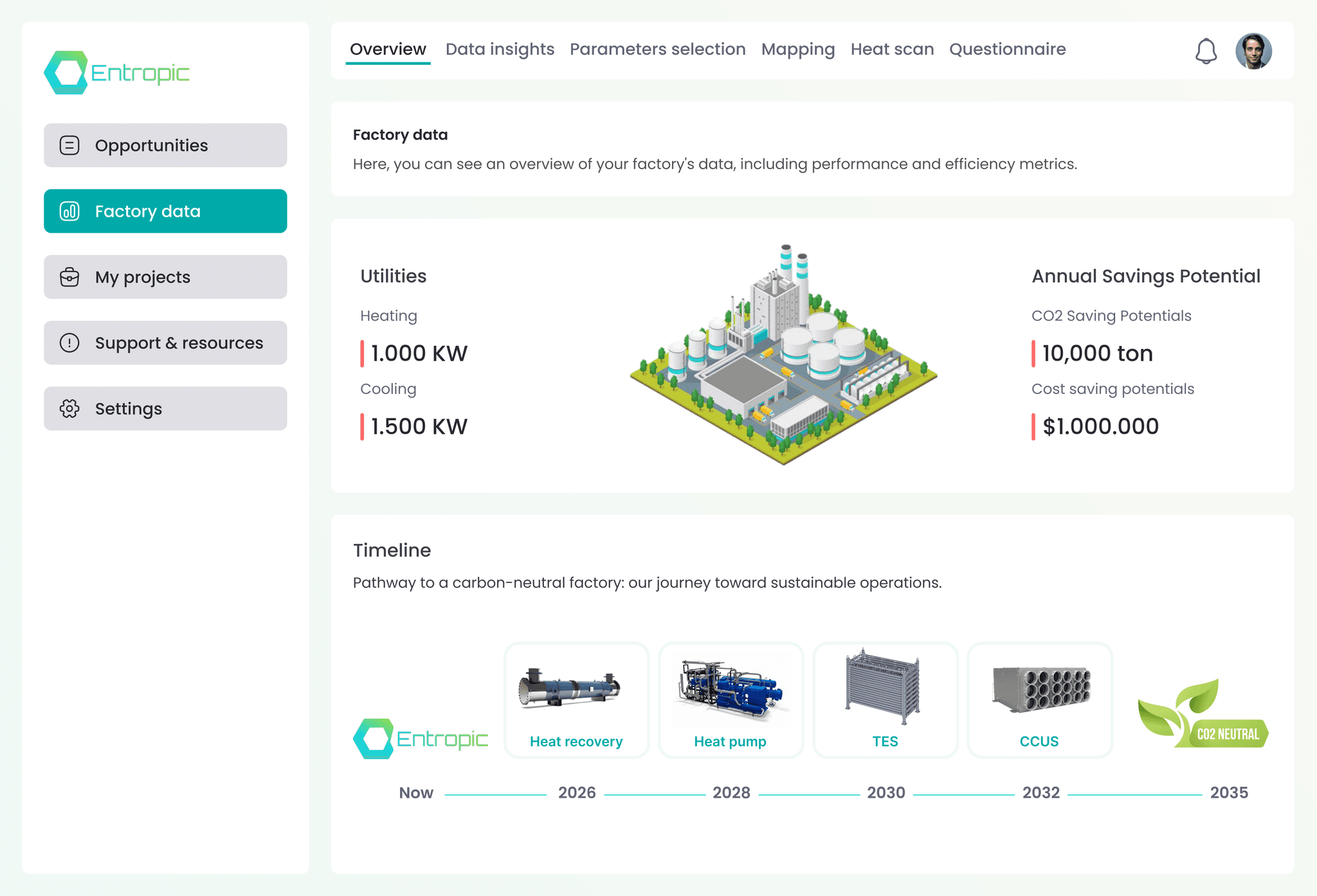

20% of the world’s CO2 emissions come from industrial heat, and 50% of this heat is wasted. These two figures stuck—and still stick around—with Melchior Krijgsman. He is the co-founder of Entropic, a startup that helps factories decarbonize their heat supply. They do this through their software, which uses digital twins of factories and a low-carbon technology library to simulate solutions and provide a profitable path to decarbonization.

In a way, it doesn’t differ much from an IKEA kitchen planner. Factory managers can upload their plant data and get a digital version. Then, like choosing a different kind of cabinet, they can simulate the impact of integrating a heat pump or a thermal storage unit, getting suggestions on what would fit better. And also, what would be the business case?

.png&w=2048&q=75)

The Green Transition Drivers

Reducing emissions, optimizing resource use, and adopting green energy are some of the practices we need to adopt to transition towards a greener economy. But who’s behind the green transition? In our series, The Green Transition Drivers, we spotlight entrepreneurs and innovators working to make our economy greener.

Speeding up industrial decarbonization

Factories are like living organisms, explains Krijgsman. “Processes constantly evolve—new equipment is added, production changes and regulations tighten. Decarbonization plans quickly become outdated, making the process inefficient and expensive. Not only do we allow to simulate, but we automate this whole process, providing advice on what is best to implement right now instead of having them engineer it all by themselves.”

Krijgsman co-founded the company with his two brothers Floris and Sebastian. Drawing from their father’s entrepreneurial spirit, they wanted to launch their business, creating something impactful.

Decarbonizing industrial processes is one of the most challenging feats to accomplish on the way to a greener economy. Technologies are yet to become mature enough to power them. Besides, factories hire external consultants to assess the factory and pitch the best solutions, but at hefty costs– and for a limited amount of time. “Our software capitalizes on opportunity costs and helps factories stay ahead of the competition,” adds Krijgsman.

Entropic platform - © Entropic

Pivoting

The history behind the Krijgsman brothers' entrepreneurial venture is one of pivoting. Two years ago, they developed a technology to turn heat into electricity, doing so via geothermal energy. Then, given that their idea was not feasible in the Netherlands, they shifted to industrial waste heat as a source. Development goes on, and the first customer joins in. More models follow, and the key realization comes.

“At that point, we thought: ‘Why don’t we focus on a decarbonization map for industrial plants?’ Factory managers don’t have time to look into it, being a complex and time-consuming process, and we can add more value. We saw a business there and started developing our software, a heat decarbonization platform,” recalls Krijgsman.

One stop shop

And after months of development, the Entropic platform can do that. The platform uses factory process data to create a digital twin of the plant. Next, it simulates solutions and provides a decarbonization roadmap, using cost engineering and electricity pricing models, including granting and financing options.

Launched a few weeks ago, the software launch was well-welcomed by the industry, with tens of industrial plants already contacting Entropic. The bold vision is: “Becoming the go-to platform for factory industrial decarbonization.” Eventually, Entropic aspires to provide a one-stop shop for factories to plan, simulate, and directly contact suppliers to buy thermal storage solutions or heat pumps.

“Last week, I attended a meeting with factory owners, suppliers, and engineering firms who were all working on a case to decarbonize an industrial plant. According to the solution they found, it would take two years. That is when I realized that our solution can make a difference and that there is a dire need for it,” Entropic founder underlines.

Entropic team - © Entropic

Surfing climate change

In addition to their startup venture, the three brothers have another passion: surfing. Born and raised in Scheveningen, they started as kids and still practice. Krijgsman sees surfing as uncertain: "You never know what wave will come next.” Entropy itself means unpredictability. As good surfers, the brothers know how to navigate this sea of uncertainty.

“What I think is crucial for policymakers to create an environment where investing in decarbonization is attractive. We need innovation, but we must surely focus on what needs to happen now, investing in proven and established technologies,” says Krijgsman.

The co-founder of Entropic believes that focusing on electrification and energy efficiency is the key to reducing energy costs and CO2 emissions. This will pave the way for adopting other technologies, such as hydrogen.

In accomplishing Entropic’s vision, execution is paramount, as per Krijgsman. “Heat decarbonization alone is a €120 billion market, so the potential exists. Getting the right team in place and following our execution plan will be the key.” Doing it with his brothers is a great strength. “We can be very honest and open and not afraid to hurt each other’s feelings. That’s essential in building a successful startup,” he wraps up.