How TNO transformed from broad innovation within 3D printing to specific breakthroughs in food and pharma

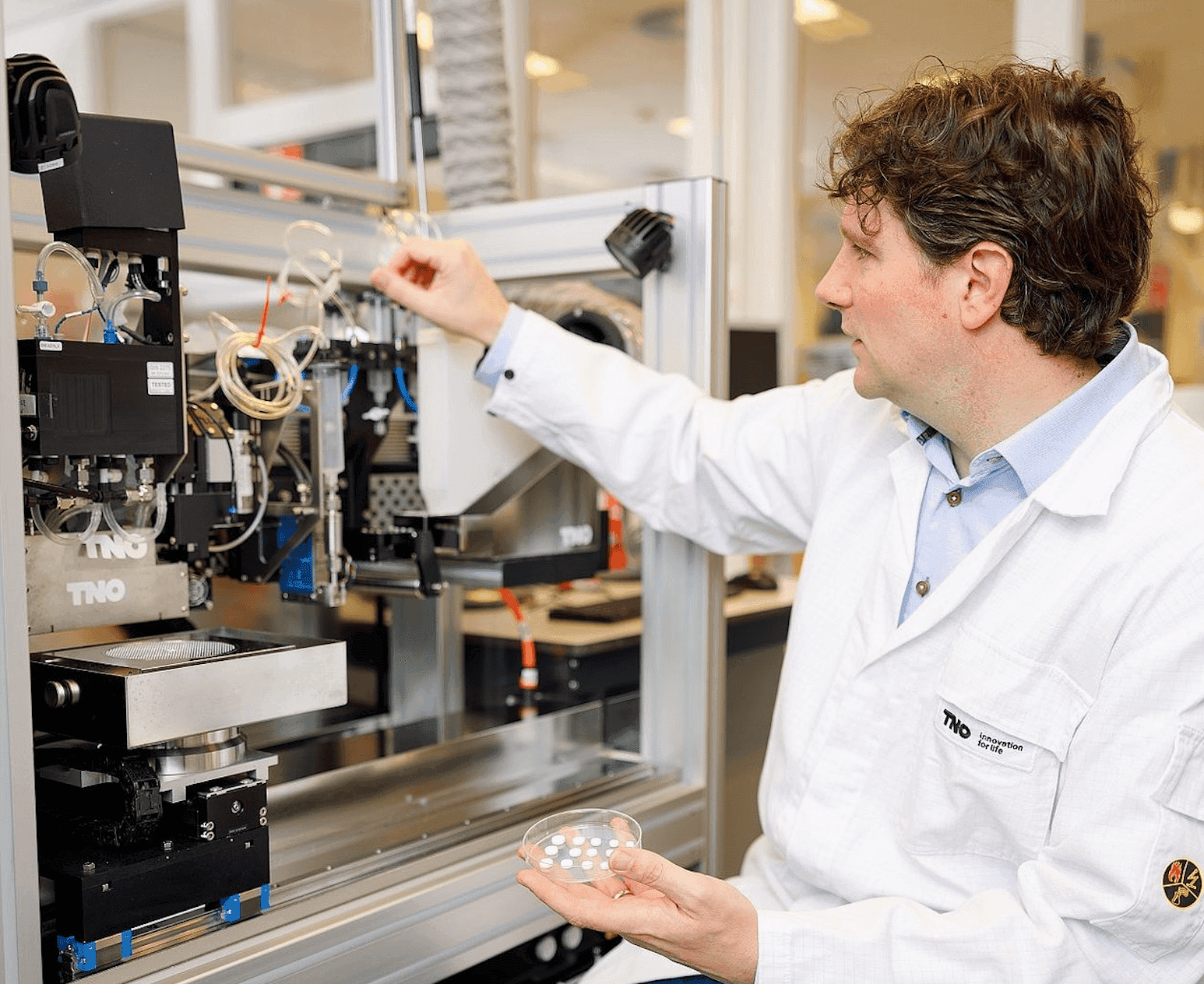

TNO plays a crucial role in the protein transition with personalized nutrition and medication. We interviewed Pieter Debrauwer about the strategic choices the organization makes.

Published on September 12, 2024

Bart, co-founder of Media52 and Professor of Journalism oversees IO+, events, and Laio. A journalist at heart, he keeps writing as many stories as possible.

Whereas TNO initially bet broadly on various 3D printing technologies, the focus is now on applications that directly impact healthcare and nutrition. Ahead of the Agrifood Innovation Event - on December 3 at the High Tech Campus in Eindhoven - Pieter Debrauwer explains the strategic choices behind this shift and TNO's technological advances.

Pieter Debrauwer looks back with pride on TNO's history in 3D printing. "We have always focused broadly on various 3D printing technologies, from metal and polymer printing to medical and food applications," says Debrauwer. However, the breadth of this focus eventually proved to be a pitfall. "Therefore, in 2018, we decided to shift our focus."

From broad to specific

The choice to focus on food and pharma was a challenging but necessary step, according to Debrauwer. "To be distinctive, you have to know both the challenges of the market and the potential of technology." This focus enables TNO to develop technologies and deploy these technologies directly to societal and industrial challenges.

TNO has focused on challenges in the food and pharmaceutical sectors within the new focus areas. "In food today, it is not only about personalization but also about the protein transition, where we are working on plant-based meat alternatives," explains Debrauwer. A critical difference between these fields is the precision required. "In pharma, precision is crucial. A few milligrams, more or less, can make a big difference in medication effectiveness. This is less relevant in food, but technology plays a key role in improving textures and flavors of plant products."

3D printing: from hype to reality

In the early years of 3D food printing, the technology was mostly about fun and experimentation. "We made complex shapes and played with new ideas, but scalability turned out to be a problem in these applications," says Debrauwer. This experience led to a rethink within TNO. "We learned that you can't do everything with 3D printing. Now we are focusing on specific applications where 3D printing can make a difference."

Plant-based and personalized medicine

In plant-based proteins, TNO is working on techniques to improve the texture and structure of plant-based products. "The challenge with plant-based products like steak and rib eye lies in mimicking the complex fiber structures in real meat. We have developed a new method to gently process vegetable proteins, which allows us to improve flavor and texture.", says Debrauwer.

TNO is also advancing in the pharmaceutical sector. "We are working on 3D-printed medication that is perfectly tailored to the needs of individual patients. This is especially important in expensive medication where precision can make a big difference," he explains. TNO recently developed a printer that hospitals use to produce personalized medication, an essential step toward better and more effective care.

Cooperation with industry

Debrauwer emphasizes that TNO is a non-profit organization that deploys its resources carefully. "Our focus on food and pharma printing is partly funded by our government contribution and mixed funding through European projects and private collaborations. We continue actively seeking new collaborations with academic and industrial partners to develop further and apply our technologies."