Hexagon and Red Bull Racing share a need for speed and nano-scale precision

Hexagon shows how the future of manufacturing can be designed through an active participation in Formula 1 Racing

Published on November 27, 2024

Red Bull Racing at Brainport Industries Campus

Bart, co-founder of Media52 and Professor of Journalism oversees IO+, events, and Laio. A journalist at heart, he keeps writing as many stories as possible.

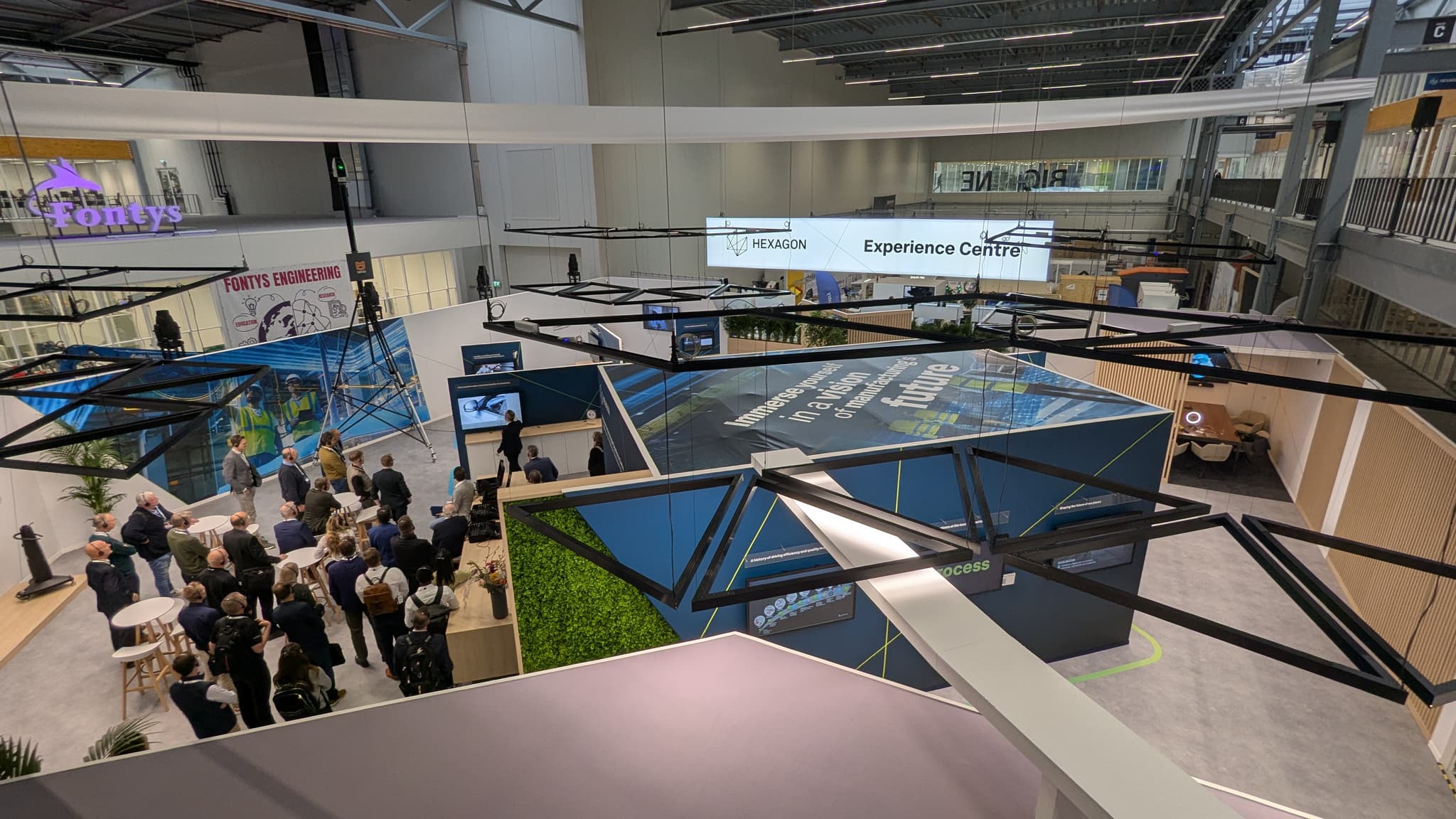

Brainport Industries Campus (BIC) in Eindhoven hosted an event today to mark the launch of Hexagon’s Experience Center. The event brought together industry leaders and technology enthusiasts. Although several new products were shown and the shiny Experience Center was unveiled, a key highlight of the day was the presentation by Hexagon and Red Bull Racing, showcasing their 17-year collaboration and the technologies driving innovation in both manufacturing and motorsport.

Hexagon, a global leader in digital reality solutions, presented its journey in the manufacturing intelligence domain. Hexagon’s President for EMEA, Stephen Chadwick emphasized the company’s mission to "digitize reality" and enable better decision-making across industries. “By leveraging AI and digital twin technologies,” he explained, “we help customers innovate, improve quality, and enhance efficiency.”

The new Hexagon Experience Center at BIC exemplifies this vision. The facility allows visitors to explore cutting-edge technologies such as advanced metrology, simulation tools, and digital twin applications. Hexagon’s approach integrates measurement, design, and data analysis to optimize manufacturing processes, ensuring products are designed and built first-time-right.

Red Bull: quality at speed

Although still shaking with enthusiasm about Max Verstappen's fourth world title in Formula 1 racing, Red Bull Racing's Morgan Maia provided a firsthand account of the partnership’s impact. The Formula 1 team operates under a strict cost cap of $145 million, making efficiency and precision critical. Hexagon’s metrology solutions and digital twins enable Red Bull Racing to design, test, and manufacture car components with unmatched accuracy, Maia said. “Our mantra is quality at speed. We make over a million parts a year, and Hexagon’s tools ensure every component meets our exact standards.”

This relentless pursuit of precision extends from the factory to the racetrack. Hexagon’s laser trackers and scanners validate the geometry of critical components like wings and suspension systems. “Even a one-millimeter deviation can cost us tenths of a second on the track,” Maia noted. “We rely on Hexagon’s technology to maintain competitive performance.”

Hexagon Experience Center at Brainport Industries Campus

Bridging manufacturing and motorsport

Hexagon’s collaboration with Red Bull Racing has helped reduce manufacturing faults by 50%, Robin Wolstenholme claimed. "It demonstrates the value of integrating advanced measurement tools and data-driven decision-making."

Jan Klingen, Hexagon’s Regional VP for EMEA North and located at Brainport Industries Campus, highlighted the shared ethos between Hexagon and Red Bull Racing. “Both organizations prioritize precision and agility,” he said. “What works on the racetrack can inspire new approaches in manufacturing, and vice versa.”

The event also showcased examples of cross-industry innovation. Technologies developed for motorsport are now finding applications in the aerospace, automotive, and energy sectors, proving that breakthroughs in one domain can have far-reaching implications.

Another significant announcement was Hexagon’s Nexus platform, a cloud-based solution designed to connect disparate technologies across the product lifecycle. Steve Graham, responsible for Nexus development, explained, “Modern manufacturing requires collaboration across silos. Nexus enables engineers to integrate tools, share data, and drive innovation more efficiently.”

Nexus enhances productivity and incorporates AI-driven features like ProPlan AI. This tool leverages natural language processing and machine learning to optimize manufacturing processes, empowering engineers to achieve greater precision and scalability.

From parts to planet

Beyond manufacturing, Hexagon is applying its expertise to global sustainability challenges. Eric Josefsson, CEO of R-Evolution, discussed initiatives like GreenCubes, a project to create 3D volumetric models of natural habitats. “Using our measurement technologies,” Josefsson explained, “we’re enabling accurate assessments of ecosystems, from seagrass meadows to rainforests, to support conservation efforts.”

This commitment to sustainability aligns with Hexagon’s broader vision of leveraging digital reality to address pressing global issues. By integrating environmental data into its digital twin models, Hexagon aims to optimize factories while preserving the planet.

The Hexagon Experience Center at BIC serves as a hub for innovation, education, and collaboration. It tries to bridge the gap between academia and industry, ensuring that young talent is equipped with the skills needed for the future. As Jan Klingen remarked, “This campus is a hangout for engineers, fostering creativity and growth in a unique environment where production, education, and innovation come together.”

Sponsored

This story is the result of a collaboration between Brainport Industries Campus and our editorial team. IO+ is an independent journalism platform that carefully chooses its partners and only cooperates with companies and institutions that share our mission: spreading the story of innovation. This way we can offer our readers valuable stories that are created according to journalistic guidelines.

Want to know more about how IO+ works with other companies? Click here