Fastmicro redefines semiconductor contamination control

This week we are highlighting the winners of the Gerard and Anton Awards. Today: Fastmicro

Published on July 12, 2025

As editor-in-chief, Aafke oversees all content and events but loves writing herself. She makes complex topics accessible and tells the stories behind technology.

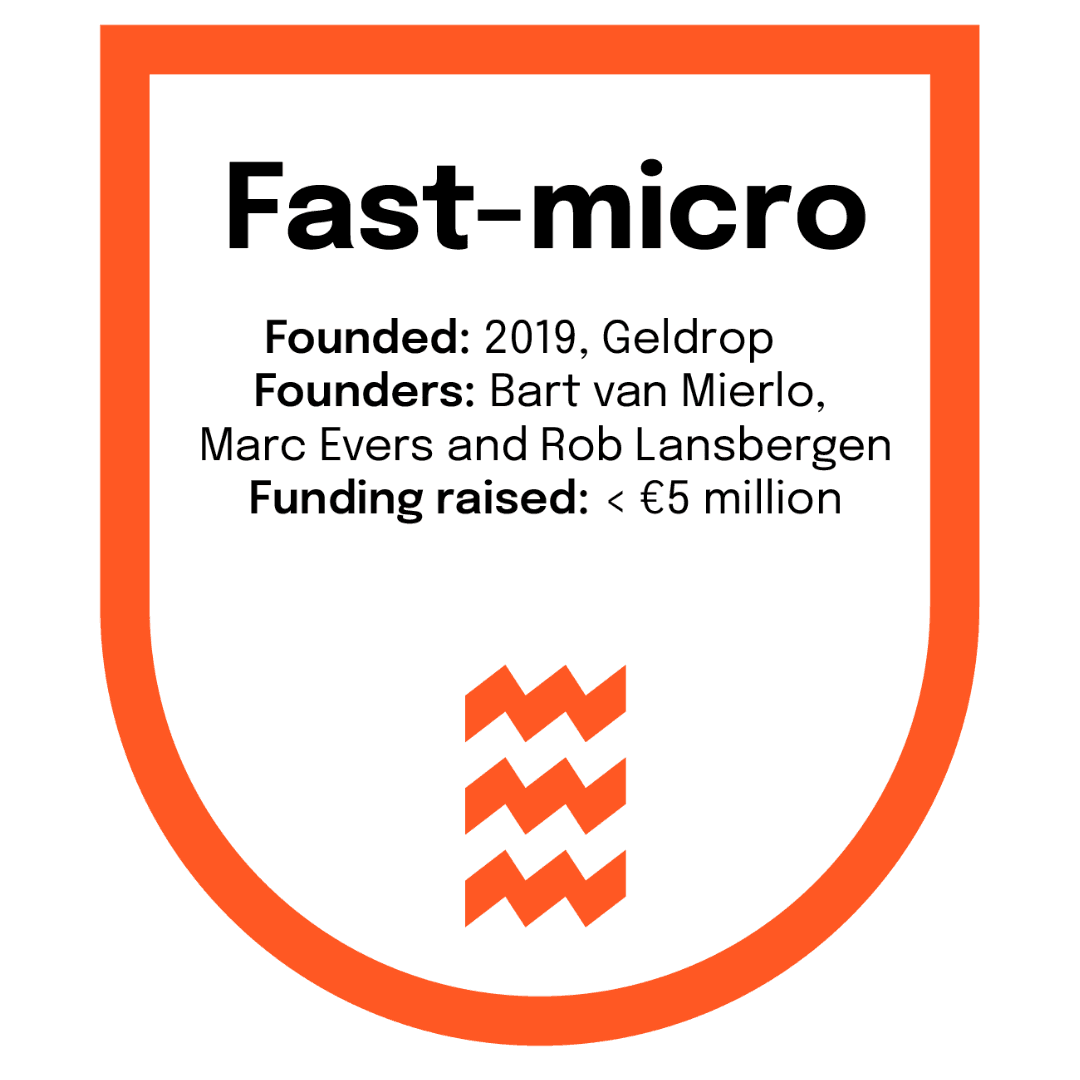

Competition is fierce, the bar is high, but the Fastmicro team knows exactly where it wants to go. Since its founding in 2019, the Geldrop-based company has been developing a technology that addresses an invisible but extremely critical issue in the high-tech industry: particle contamination. These tiny dust particles can disrupt or destroy entire production processes.

“Our task is clear,” says co-founder Bart van Mierlo. “We want to convince the industry of the necessity and power of our particle cleanliness solution. Because you can't control what you can't measure.”

Originating from a request from ASML

The reason for Fastmicro's establishment was concrete and urgent: ASML was seeking more accurate ways to measure contamination in its extremely sensitive systems. The question was forwarded to the Netherlands Organisation for Applied Scientific Research (TNO), and from that collaboration, Fastmicro was born —a commercial spin-off focused on marketing a solution to a fundamental problem.

Together with co-founders Marc Evers and Rob Lansbergen, Van Mierlo decided to take on the challenge. “We immediately saw the impact this could have on the entire high-end production chain,” he says. “From that moment on, it became our mission.”

The challenger in an established market

Fastmicro operates at the heart of the semiconductors and displays sector, markets where precision and predictability are crucial. There, the company competes with established metrology OEMs that have been calling the shots for years.

“We are the challenger,” says Van Mierlo. “Whereas established companies focus on traditional measurements, we bring speed, simplicity, and real-time insight. That is exactly what the industry needs right now.”

Faster from prototype to product

A major challenge for Fastmicro was to turn a working prototype into an industrially mature product within a reasonable time frame and with a relatively young team. And they succeeded: the first delivery to a major semiconductor original equipment manufacturer (OEM) is now a reality and represents an important milestone for the team.

Van Mierlo: “That moment felt like a validation of all our choices. Developed in-house, built in-house, and delivered directly to a major customer – we are proud of that.”

External Content

This content is from youtube. To protect your privacy, it'ts not loaded until you accept.

Looking to the future

Fastmicro sees great opportunities in the next five to ten years, not only in current markets, but also in emerging technologies such as compound semiconductors and hybrid bonding. “These trends require even stricter control of contamination,” says Van Mierlo. “Our solution fits in seamlessly with that.”

Brainport as a springboard

The Brainport region is fertile ground for the startup. Not only as a breeding ground for high-tech ideas, but also because of the availability of experienced suppliers and an open ecosystem. “We were able to take our first steps here,” says Van Mierlo. “The willingness to think along, help, and advise is unprecedented. You just have to dare to ask.”

At the same time, the entrepreneur also sees room for growth in the ecosystem. For example, there is a need for more substantial financing to enable rapid upscaling and for better support for startups in peripheral areas such as housing, IT, and market validation. “As a startup, you want to focus on the core,” explains Van Mierlo. “Everything that doesn't belong there should be easy to arrange.”

International ambitions

Although Fastmicro is firmly anchored in Brainport, the team is also looking beyond the border. In particular, they are looking at other technological clusters in the semiconductor industry, such as Grenoble, Dresden, and Leuven. “That's where our market is,” says Van Mierlo. “But our roots are here, and the foundation we have built in Brainport is now helping us to scale up internationally.”

G&A 2025

Every year, we spotlight 10 start-ups from the Brainport region. Each receives a Gerard & Anton Award.